How are synthetic urine kits designed to mimic real urine?

Synthetic urine has evolved significantly from its early applications in laboratory settings, where it was primarily used to calibrate equipment and test detection methodologies. Modern synthetic urine kits represent sophisticated chemical formulations designed to replicate human urine’s physical, chemical, and biological properties. This article examines the scientific principles behind synthetic urine formulations, and the technologies manufacturers employ to create these laboratory-grade simulants.

Chemical composition challenge

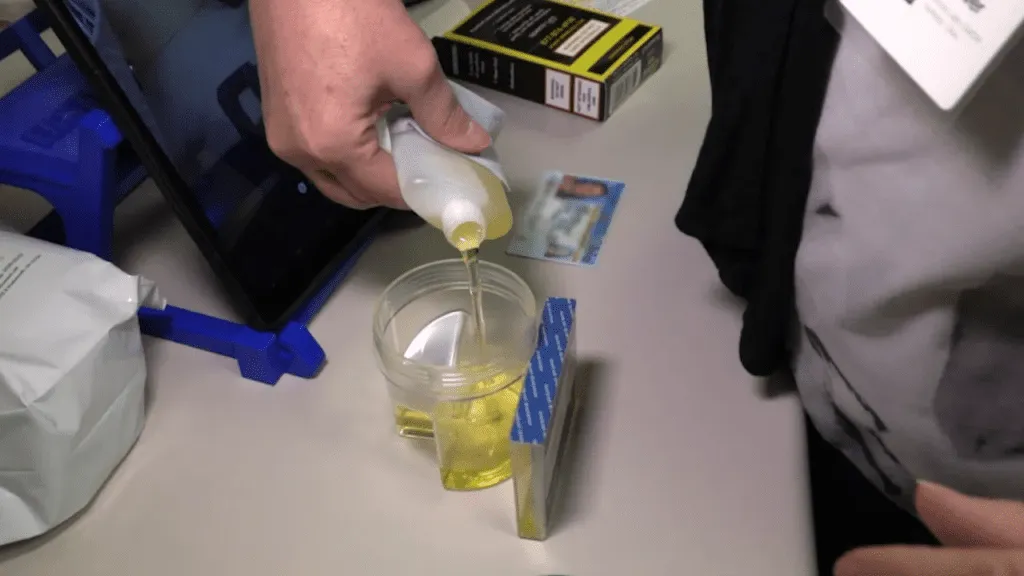

Human urine is a complex biofluid containing numerous compounds, varying composition based on diet, hydration, health status, and medication use. Synthetic urine manufacturers face the challenge of replicating this intricate chemical profile while maintaining stability and shelf life.

Key chemical components

Synthetic urine formulations typically include:

- Urea – The primary nitrogenous compound in urine, comprising approximately 9.3 g/L in healthy adults

- Creatinine – A breakdown product of muscle metabolism present at concentrations of 0.5-2.0 g/L

- Uric acid – Typically present at 0.25-0.75 g/L

- Inorganic salts – Including sodium chloride, potassium chloride, calcium phosphate, and magnesium sulfate

- Water – Comprising 91-96% of urine volume

- Balanced pH – Typically formulated within the normal range of 4.5-8.0

Advanced Synthetic Urine products may also include trace elements like copper, zinc, and selenium, as well as epithelial cells to mimic natural samples more precisely. They are carefully balanced to create a stable, chemically viable solution throughout its shelf life.

Temperature regulation technology

The significant challenges in synthetic urine design involve temperature regulation, as fresh human urine typically exits the body at 94-98°F (34-37°C).

Heating elements

Advanced synthetic urine kits incorporate disposable or reusable heating elements that maintain the sample within the physiological temperature range for several hours. These typically utilize:

- Exothermic chemical reactions – One-time use heat packs that activate when exposed to air

- Battery-powered heating – Electronic temperature regulation systems with thermostatic control

- Microwave compatibility – Specially designed containers that can be safely heated in microwave ovens

Preservation and stability engineering

Creating synthetic urine that remains stable during storage presents substantial challenges:

Antimicrobial additives

Without preservation, synthetic urine would become a growth medium for bacteria and fungi. Manufacturers address this through:

- Biocides – Low concentrations of preservatives that inhibit microbial growth

- Sterile packaging – Production under aseptic conditions to prevent initial contamination

- Vacuum sealing – Removing oxygen to limit oxidative degradation and microbial growth

Chemical stability

Preserving the chemical integrity of synthetic urine components, particularly urea, which naturally degrades over time, requires specialized stabilization technologies:

- pH buffers – Maintain optimal pH to prevent component degradation

- Antioxidants – Prevent oxidative degradation of organic components

- UV-resistant packaging – Protect light-sensitive components like vitamin B complexes

Quality control

A rigorous quality control process ensures synthetic urine products consistently match human urine:

- Batch testing – Each production batch undergoes chemical analysis for component concentration

- Stability testing – Accelerated ageing tests to verify shelf-life claims

- Performance validation – Testing against multiple analytical platforms to ensure consistent results

Synthetic urine represents a triumph of biochemical engineering, replicating the complex properties of human urine through precise formulation and technological innovation. Initially developed for laboratory calibration, synthetic urine is used across various scientific and industrial contexts. To maintain their utility in laboratory and testing environments, synthetic urine formulations will likely continue incorporating additional biomarkers.